Lini Filter is a professional manufacturer of sintered mesh, sintered felt, and sintered filter elements in Xinxiang. Today, we will introduce the differences between sintered felt and sintered mesh:

1. Differences in manufacturing processes

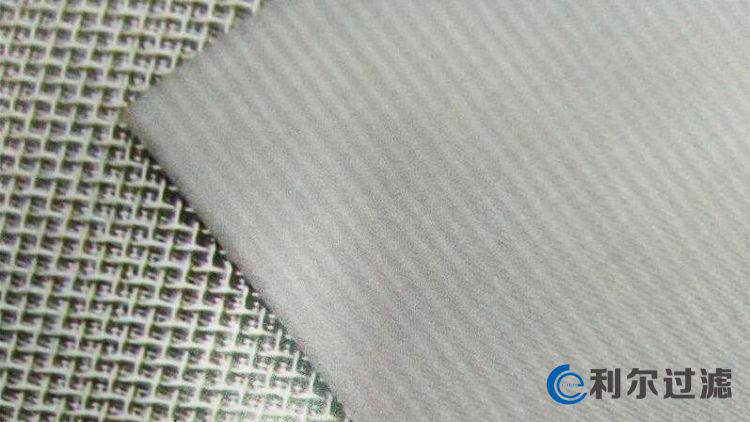

Sintered mesh is made by stacking multiple layers of identical or different metal woven mesh, and then sintering and rolling at a high temperature of 1100 ° C; Sintered felt is different

Metal fibers with a wire diameter are made by non-woven laying, stacking, and sintering at high temperatures up to 1100 ° C.

2.Differences in sintering processes

Sintered wire mesh is a multi-layer metal wire mesh that is stacked according to a certain structure and then sintered; And sintered felt is a random stacking of various metal fibers

Sintered together.

3.Differences in pollutant carrying capacity

Due to the unique manufacturing process of sintered felt, different pore gradients are formed during the sintering process. Compared to sintered mesh, sintered felt

Has a stronger ability to absorb pollutants.

4. Differences in porosity

Before sintering, the metal mesh is arranged neatly layer by layer in a regular manner, with interconnected mesh holes and an overall orderly structure

Due to the disorderly discharge method of sintered felt, the porosity of the sintered mesh is nearly 100%, while the porosity of sintered felt is not ideal, with a certain degree of blind hole rate.

5. Differences in filtering accuracy

Sintered felt, due to its certain blind hole rate, has lower filtration accuracy compared to sintered mesh. The filtration accuracy range of sintered felt is between 5-60um,

The filtration accuracy of the sintered mesh is between 1-300um.